Specifications and Technical Parameters |

||||

No. |

Machine Model |

Unit |

Specification |

Remarks |

| 1 | VMC1160 | – | – | |

| 2 | Table Size | mm | 1200×600 | |

| 3 | X/Y/Z Axis Travel | mm | 1100/600/600 | |

| 4 | Spindle Nose to Table Surface Distance | mm | 120-720 | |

| 5 | Spindle Center to Column Guide Surface Distance | mm | 650 | |

| 6 | Maximum Table Load Capacity | Kg | 800 | |

| 7 | Table T-slots | mm | 5-18×100 | |

| 8 | X/Y/Z Axis Rapid Feed Rate | m/min | 20/20/20 | |

| 9 | X/Y/Z Guideway Specifications | mm | RGH45/45/45 | |

| 10 | X/Y/Z Ball Screw Specifications | mm | Φ40×12 | |

| 11 | Positioning Accuracy | mm | ±0.005 | |

| 12 | Repeated Positioning Accuracy | mm | ±0.003/300 | |

| 13 | Minimum Command Unit | mm | ±0.001 | |

| 14 | Maximum Spindle Speed | rpm | 8000 (Annular Water Jet) | |

| 15 | Spindle Taper | mm | BT40 – 150 | |

| 16 | Disc-type Tool Magazine Capacity | pcs | 24T | |

| 17 | Control System | – | KND 220Plus | |

| 18 | X/Y/Z Axis Motor Power | Nm | 18/18/27 | |

| 19 | Spindle Motor Power | kW | 11 | |

| 20 | Machine Weight | Kg | Approx. 6200 | |

| 21 | Overall Dimensions | mm | 2900×2400×2650 | |

| Major Component Brands and Countries of Origin | ||||

| No. | Product Name | Manufacturer | Country of Origin | |

| No. | Component Name | Manufacturer | Origin | |

| 1 | CNC Controller | Optional | – | |

| 2 | Spindle Drive Motor | Optional | – | |

| 3 | Three-Axis Drive Motor | Optional | – | |

| 4 | Integral Spindle | Okada | Taiwan | |

| 5 | Spindle Tool Clamp Cylinder | China-Japan | Taiwan | |

| 6 | X/Y/Z Axis Bearings | NACHI | Japan | |

| 7 | X/Y/Z Axis Roller Linear Guides | HIWIN | Taiwan | |

| 8 | X/Y/Z Ball Screws | HIWIN | Taiwan | |

| 9 | Centralized Automatic Lubrication System | Protech | Taiwan | |

| 10 | Air Source Filtration Unit | AirTAC | Taiwan | |

| 11 | Three-Axis Couplings | S+P | Taiwan | |

| 12 | Cooling Device | Weisen | China | |

| 13 | External Sheet Metal | Standard | China | |

| 14 | Electrical Components & Overload Protectors | Schneider | France | |

| 15 | Robotic Tool Changer/Automatic Tool Changer (ATC) | Okada | Taiwan | |

| 16 | Electrical Cabinet Heat Exchanger | KeHengAo | Jiangsu, China | |

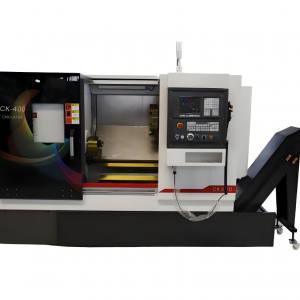

VMC1160

High-Precision CNC Vertical Lathe for Efficient Metal Machining VMC1160

1.The machine adopts a mechatronic and hydraulic integration design, featuring a compact overall structure that optimizes space utilization while ensuring stable mechanical performance.

2.Both X-axis and Z-axis are equipped with precision linear guideways, and their ball screws adopt a pre-tensioning design. This configuration significantly enhances the machine’s rigidity and positioning accuracy, laying a solid foundation for high-precision machining.

3.The machine is equipped with an 8-station hydraulic turret, which delivers reliable operation, high switching efficiency, and excellent cutting stability—effectively reducing tool change time and improving overall processing efficiency.

4.The spindle adopts a high-rigidity structural design, supporting variable speed adjustment. It can realize both constant surface speed (CSS) cutting (for ensuring uniform surface finish of workpieces) and heavy-duty cutting, adapting to diverse processing demands of 4.different materials.

5.An automatic centralized lubrication system is configured to ensure sufficient and uniform lubrication of key components (such as guideways and ball screws). This not only reduces mechanical wear but also enhances the reliability and service life of the machine.

Reviews

There are no reviews yet.