Project |

Unit |

Parameter |

Remark |

|

| Maximum rotation diameter of the saddle (disc type) Zero passing the pallet |

mm | Ø560 | ||

| Rotation diameter of screw guard through X direction (shaft) There should be no knife holder on the turret |

mm | Ø485 | ||

| Center distance | mm | 600 | ||

| Maximum cutting length | mm | 490 | 10″ chuck, 100-8T tool holder | |

| Standard cutting diameter | Plates | mm | Ø435 | |

| Axles | mm | Ø360 | ||

| Spindle end form | type | A2-8 | ||

| Spindle inner hole large end diameter | mm | Ø90/1:20 | ||

| Spindle through hole diameter | mm | Ø86 | ||

| Maximum spindle speed range | r/min | 2500 | 11KW | |

| Spindle bearings | type | NN3024K(CSPG) | 1 item | |

| type | NN3022K(CSPG) | 1 item | ||

| type | 7024AC/DB(CSPG) | 2 items/1 set | ||

| Lathe bed structure | type | Integral 45° inclined bed | ||

| X-axis travel | mm | 250 | ||

| X-axis screw | type | 3210×588 | ||

| X-axis bearings | type | 2562 | 3 items/1 set | |

| type | 2047 | 2 items/1 set | ||

| X-axis rail | type | RGH35CA-2R-650 | 2 items/1 set E=25 | |

| Z-axis travel | mm | 625 | ||

| Z-axis screw | type | 4010×1455 | ||

| Z-axis bearings | type | 3062 | 3 items/1 set | |

| type | 3062 | 2 items/1 set | ||

| Z-axis rail | type | RGH45CA-2R-1310 | 2 items/1 set E=25 | |

| Turret | type | Horizontal 8-station turret | ||

| Tool installation size | mm | 25*25 | ||

| Tailstock quill diameter/stroke | mm | Ø75/L150 | ||

| Tailstock quill taper | mm | MT5# | ||

| Processing accuracy | level | IT6-IT7 | ||

| Positioning accuracy X/Z | mm | 0.022/0.032 | ||

| Repeat positioning accuracy | mm | X-axis:0.009 | ||

| mm | Z-axis:0.012 | |||

| Roughness | um | Ra≤1.6 | ||

| Power | kVA | 20 | ||

| Size | mm | 2900*1900*2000 | ||

| Weight | kg | 3500 | ||

| System | type | GSK-988T | GSK | |

| Main motor | KW | 11 | GSK | |

| X-axis servo motor | N/M | 130SJT-M150D(15N/M) | GSK | |

| Z-axis servo motor | N/M | 130SJT-M150D(15N/M)With brake | GSK | |

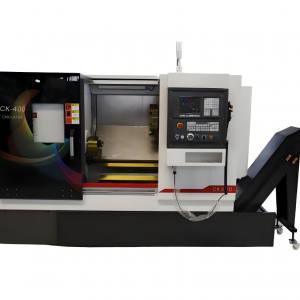

CK series CNC equipment, Lathe equipment

CK-500L/600

The Y-axis function and the longitudinal and transverse milling function can complete the compound machining of turning, milling, drilling and tapping of the outer circle and end face of the workpiece in one damping, which avoids the error of multiple clamping and ensures the precision of the workpiece. It is particularly advantageous for the processing of complex workpieces.

Reviews

There are no reviews yet.