Project |

Unit |

Parameter |

Remark |

|

| Maximum rotation diameter of the saddle (disc type) Zero passing the pallet |

mm | Ø485 | ||

| Rotation diameter of screw guard through X direction (shaft) There should be no knife holder on the turret |

mm | Ø365 | ||

| Center distance | mm | 500 | ||

| Maximum cutting length | mm | 460 | 10″ chuck, 100-8T tool holder | |

| Standard cutting diameter | Plates | mm | Ø315 | |

| Axles | mm | Ø265 | ||

| Spindle end form | type | A2-6 | ||

| Spindle inner hole large end diameter | mm | Ø66.7/1:20 | ||

| Spindle through hole diameter | mm | Ø62 | ||

| Maximum spindle speed range | r/min | 3500 | 7.5KW | |

| Spindle bearings | type | NN3024K(CSPG) | 1 item | |

| type | NN3022K(CSPG) | 1 item | ||

| type | 7024AC/DB(CSPG) | 2 items/1 set | ||

| Lathe bed structure | type | Integral 45° inclined bed | ||

| X-axis travel | mm | 200 | ||

| n.m | 10 /22 | |||

| X-axis bearings | type | 2562 | 3 items/1 set | |

| type | 2047 | 2 items/1 set | ||

| X-axis rail | type | RGH35CA-2R-590 | 2 items/1 set E=15 | |

| Z-axis travel | mm | 590 | ||

| Z-axis screw | type | 3210×990 | ||

| Z-axis bearings | type | 2562 | 3 items/1 set | |

| type | 2562 | 2 items/1 set | ||

| Z-axis rail | type | RGH45CA-2R-1100 | 2 items/1 set E=10 | |

| Turret | type | Horizontal 8-station turret | ||

| Tool installation size | mm | 20*20 | ||

| Tailstock quill diameter/stroke | mm | Ø52/L60 | ||

| Tailstock quill taper | mm | MT4# | ||

| Processing accuracy | level | IT6-IT7 | ||

| Positioning accuracy X/Z | mm | 0.022/0.032 | ||

| Repeat positioning accuracy | mm | X-axis:0.009 | ||

| mm | Z-axis:0.012 | |||

| Roughness | um | Ra≤1.6 | ||

| Power | kVA | 15 | ||

| Size | mm | 2700*1700*1700 | ||

| Weight | kg | 3000 | ||

| System | type | GSK-988T | GSK | |

| Main motor | KW | 7.5 | GSK | |

| X-axis servo motor | N/M | 130SJT-M100D(10N/M) | GSK | |

| Z-axis servo motor | N/M | 130SJT-M100D(10N/M)With brake | GSK | |

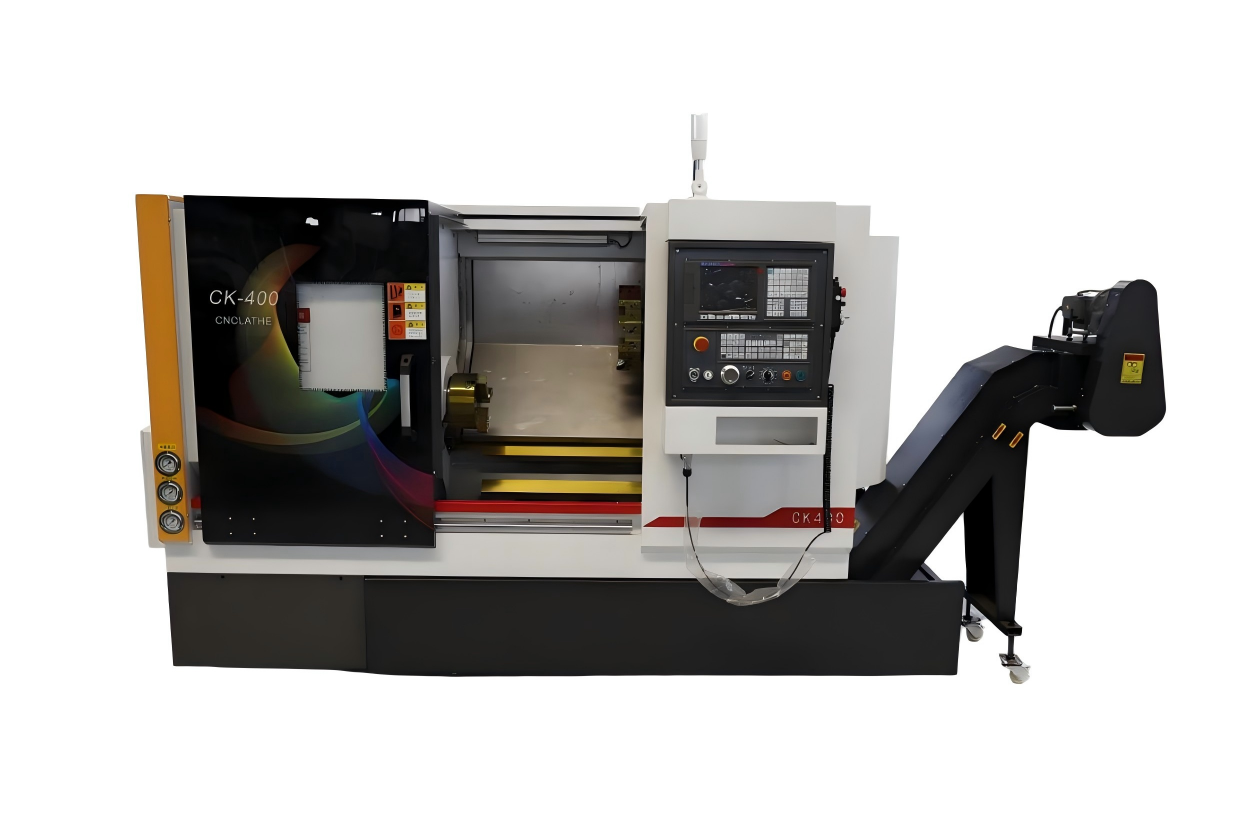

CK series CNC equipment, Lathe equipment

CK400L/450

This machine tool features a 45° integral inclined bed structure, delivering high speed,precision, and reliability. Key components including the bed base, bed body, and headstock are forged from high-strength materials to ensure long-term stability.

Equipped with high-precision preloaded linear roller guides, it ensures precise positioning and smooth material flow, making it ideal for high-speed precision machining.

Reviews

There are no reviews yet.